A PRACTICAL GUIDE TO WELDING CLOSED RIBS (U-RIBS), 2013

ABSTRACT

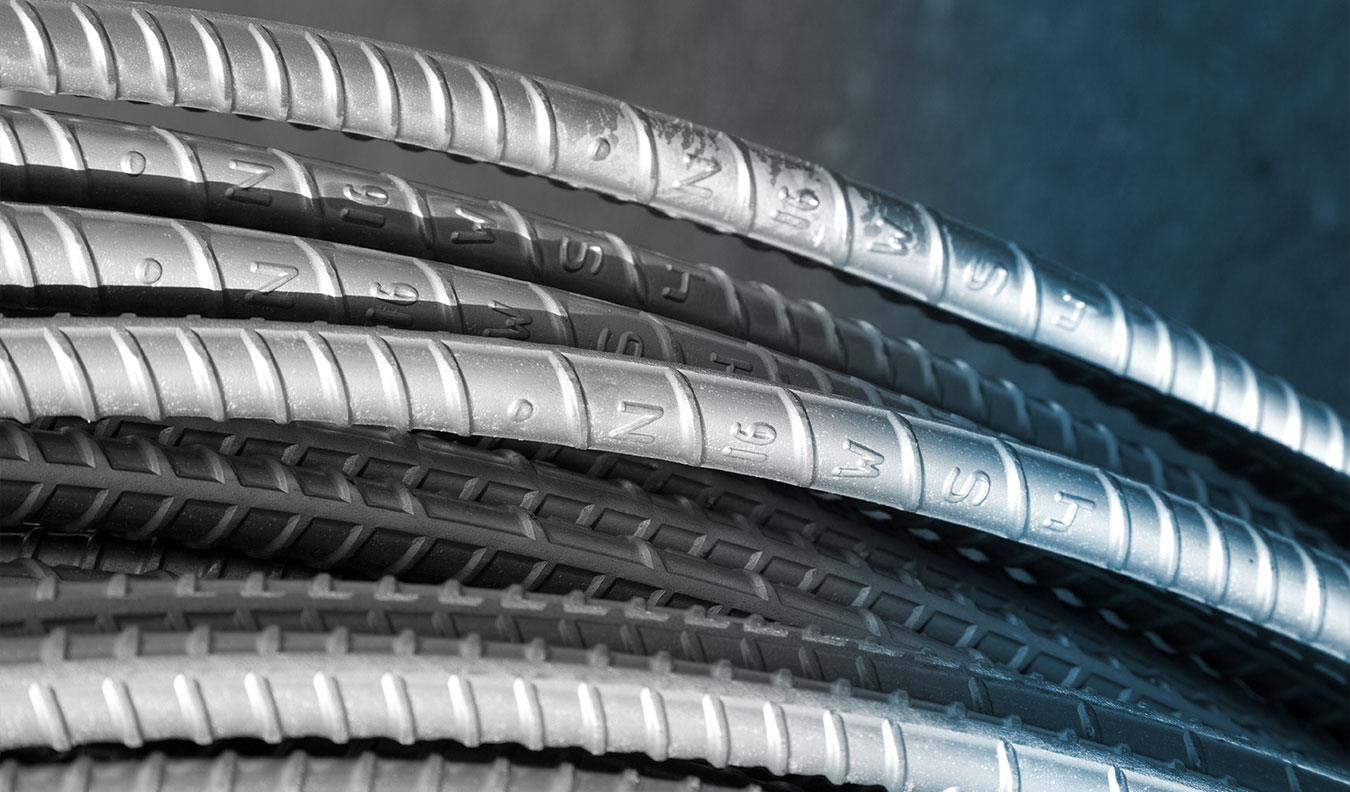

Closed ribs serve as the primary stiffening elements for orthotropic box girders, which when constructed in series, comprise the orthotropic steel bridge deck. Two partial joint penetration (PJP) groove welds connect each of the closed ribs to the bridge deck plates. Due to long-term fatigue cracking that can occur with poor weld quality, consistent quality in the PJP closed rib weld is essential to the structure’s ability to meet the specified design life.

The fabrication of several bridges employing the orthotropic steel deck design illustrated the challenges fabricators and contractors face when performing closed rib welding (also referred to as U-rib welding). Bridges examined in this paper include the new Tacoma Narrows Bridge in Tacoma, Washington, the Alfred Zampa Memorial (new Carquinez) Bridge in Crockett, California, the Bronx-Whitestone Bridge in New York City, New York, and the new eastern span of the San Francisco-Oakland Bay Bridge in Oakland, California.

The PJP groove weld is a non-standard joint and can create numerous challenges for fabricators. Issues that have arisen through the fabrication of closed rib welds on various orthotropic steel bridge projects are cracked tack welds, solidification cracking, and consistent maintenance of the specified weld penetration level.

This paper will discuss the practical steps fabricators and contractors can take to successfully perform closed rib welding, which include developing a careful welding procedure to control weld parameters, performing multi-pass welding, standardizing tack weld length and size, and performing NDT to identify areas requiring repair.

– Patrick Lowry, Keith Hoffman, and Aaron Prchlik. “A Practical Guide to Welding Closed Ribs (U-Ribs),” Seventh National Seismic Conference on Bridges & Highways, Oakland, CA, May 2013.