CHALLENGES IN FABRICATION OF PRECAST PRESTRESSED CONCRETE SUPER GIRDERS, 2013

ABSTRACT

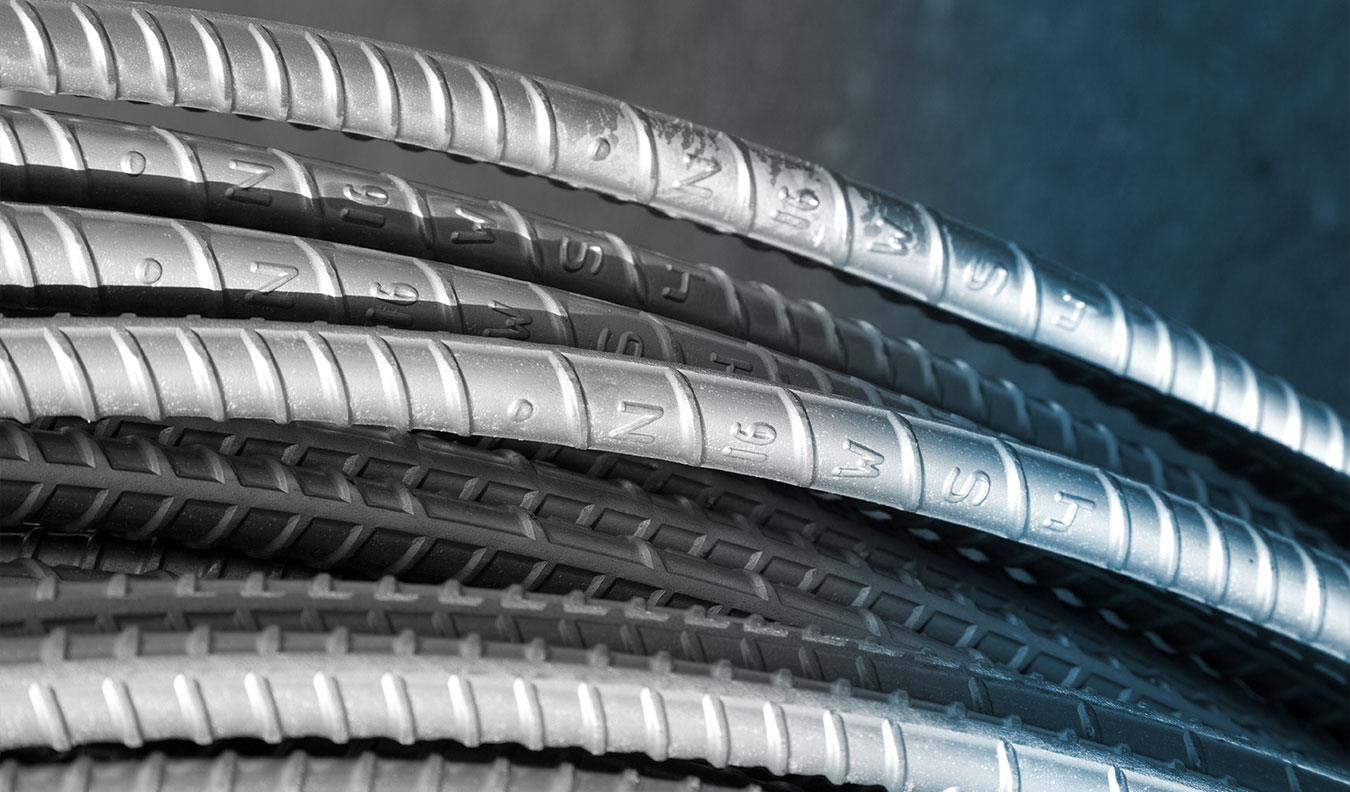

Construction is underway on a California Department of Transportation (Caltrans) widening project on SR 99 in Nicolaus, CA. A major element of this project is precast/prestressed bulb tee super girders with a maximum height of 8’6”, up to 120’ long and weighing up to 90 tons each for a bridge over the Feather River. Fabrication of these tall and slender girders posed unique challenges such as arrangement of post tensioning ducts in a thin web, high performance concrete with compressive strength of 8,500 psi, transportation and handling issues. As the owner, California Department of Transportation (Caltrans) enforced a rigorous quality assurance scheme to ensure fabrication met its challenges. This process included submission of a detailed Quality Control Plan by the fabricator. Caltrans material engineers and inspectors were involved from the onset of fabrication and worked closely with the fabricator for a quality product. This paper details the unique difficulties and challenges encountered during the course of the fabrication and how Caltrans’ and the fabricator’s combined proactive approach resulted in a successful delivery of the product.

– Mohammad J. Fatemi, PhD, PE, Robert Kim, PE, and Mike Hein, PE, “Challenges in Fabrication of Precast Prestressed Concrete Super Girders,” PCI Convention and National Bridge Conference, Grapevine, TX, September 2013.